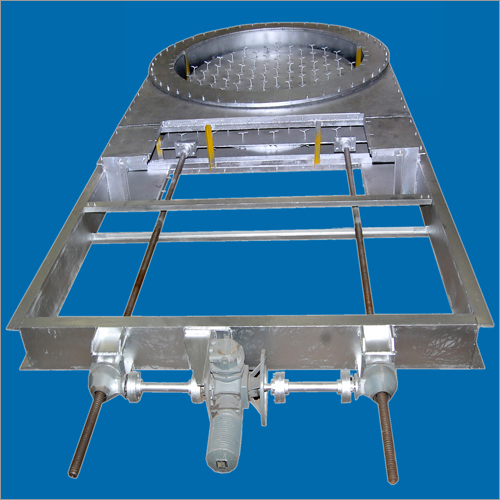

Multi Louver Damper

Multi Louver Damper Specification

- Thickness

- 1.2 mm - 3 mm

- Machines Type

- Ventilation Equipment

- Installation Type

- Flanged / Duct Mounted

- Form

- Damper Frame with Multiple Louvers

- Load Capacity

- Medium Duty

- Application

- HVAC Systems, Industrial Ventilation, Air Handling Units

- Features

- Manual or Motorized Operation, Air Leakage Prevention

- Purity

- Industrial Grade

- Color

- Silver / Grey / As Required

- Usage

- Airflow Regulation

- Diameter

- Not Applicable (Rectangular design)

- Material Grade

- IS 2062 / EN Standard

- Product Type

- Multi Louver Damper

- Main Material

- Galvanized Steel / Mild Steel / Aluminum

- Surface Treatment

- Powder Coated / Painted / Galvanized

- Size

- Customized as per requirement

- Weight

- Variant (Depends on size and material)

- Feature

- Corrosion Resistance, Adjustable Louvers, Robust Construction

- Shape

- Rectangular / Square

- Control Option

- Manual Handle / Electric Motor / Pneumatic Actuation

- Packaging

- Wooden Box or Custom Packing

- Blade Type

- Opposed / Parallel

- Accessories

- Actuators, Position Indicators, Seals

- Maintenance

- Low, Easy Access for Cleaning

- End Connection

- Flanged / Slip on / Welded Ends

- Max Air Velocity

- 15-20 m/s

- Leakage Rating

- Low Air Leakage Design

- Operating Temperature Range

- -10°C to +80°C

- Blade Operation

- Linked and Individually Adjustable

- Blade Material

- Same as main frame or as specified

About Multi Louver Damper

A Multi-Loover (or Multi-Louver) Damper is a type of damper commonly used in HVAC systems (Heating, Ventilation, and Air Conditioning) to control the flow of air or gas through ducts or chimneys. It is designed to regulate the flow of air or gas by changing the angle of its multiple blades or louvers that are fitted inside a duct or a chimney.

The Multi-Louver Damper consists of a frame and multiple blades or louvers that can rotate around a horizontal or vertical axis. The blades can be adjusted manually or automatically through an actuator that can be controlled remotely or by a control system.

When the blades are closed, they prevent the flow of air or gas through the duct or chimney. When they are opened, the air or gas can flow through the duct or chimney with minimal resistance. By adjusting the angle of the blades, the Multi-Louver Damper can control the volume and direction of the air or gas flow.

Superior Airflow Control and Flexibility

This damper provides advanced airflow management with customizable blade adjustmentseither linked or individually operable. Its design suits diverse HVAC and industrial ventilation requirements, allowing installations in air handling units or duct systems. Multiple control options ensure compatibility with manual or automated solutions.

Robust Construction with Corrosion Resistance

Crafted from galvanized steel, mild steel, or aluminum, the dampers frame and blades are built to withstand challenging environments. The available powder coating, painting, or galvanization enhances durability and corrosion resistance, ensuring reliability in medium duty, industrial-grade operations.

Low Maintenance and Easy Installation

With easy access for cleaning and low maintenance requirements, these dampers minimize downtime. Custom sizes and shapesrectangular or squareenable straightforward integration into existing systems, supported by a choice of mounting and end connection methods.

FAQs of Multi Louver Damper:

Q: How does the opposed or parallel blade configuration affect damper performance?

A: Opposed blade arrangements allow for uniform airflow distribution, making them ideal for precise modulation. In contrast, parallel blades are typically used in applications where quick, full opening or closing is required. The configuration is chosen according to specific airflow control needs.Q: What materials are available for constructing these dampers?

A: The Multi Louver Damper can be made from galvanized steel, mild steel, or aluminum. Material selection depends on environmental conditions, corrosion resistance requirements, and client specifications, with all options conforming to IS 2062 or EN Standards.Q: When should I choose manual, electric, or pneumatic operation?

A: Manual operation is suited for accessible locations and infrequent adjustments. Electric actuators are preferable for automated or remote control in sophisticated HVAC systems, while pneumatic actuation is chosen for integration with compressed air systems or where quick response is needed.Q: Where are these dampers typically installed?

A: Multi Louver Dampers are commonly installed in HVAC ductwork, industrial ventilation networks, air handling units, and any place requiring controlled airflow within medium duty, rectangular or square shaft configurations.Q: What is the maintenance process for these dampers?

A: They are designed with easy access for routine cleaning and inspection. Regular maintenance primarily involves checking and lubricating moving parts, inspecting seals, and ensuring actuators (if equipped) function reliably. Their low-maintenance design minimizes service time.Q: What are the key benefits of a low air leakage design?

A: A low air leakage design ensures minimal loss of conditioned or processed air, enhances system efficiency, and contributes to energy savings. It also helps maintain desired pressure and environmental standards in sensitive applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Damper Category

TAD Shut-off Damper

Machines Type : Ducting, Air Control Systems

Shape : Rectangular / Circular

Installation Type : Flanged / Slipon / Welded

Thickness : 1.2 mm to 3 mm

Form : Fabricated Sheet Metal

Load Capacity : Designed for low, medium, and high pressure ducts

Butterfly Damper

Machines Type : HVAC Systems, Industrial Air Handling

Shape : Round

Installation Type : Flanged/Mounted

Thickness : 5 mm (customizable)

Form : Fabricated

Load Capacity : Suitable for normal industrial air flow loads

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry