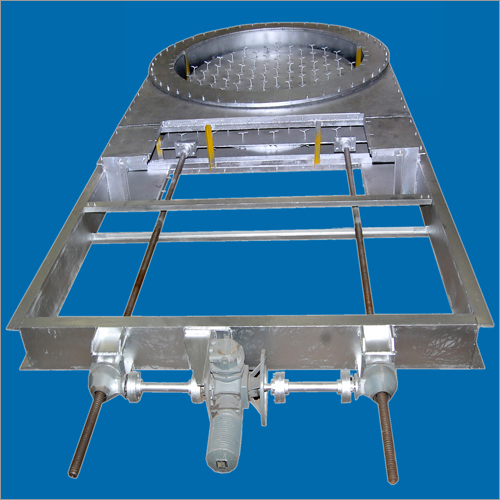

TAD Shut-off Damper

TAD Shut-off Damper Specification

- Purity

- Industrial Grade

- Material Grade

- IS 2062 / SS304 / SS316

- Machines Type

- Ducting, Air Control Systems

- Features

- Manual or motorized operation, precise shut-off, long service life

- Form

- Fabricated Sheet Metal

- Thickness

- 1.2 mm to 3 mm

- Installation Type

- Flanged / Slip-on / Welded

- Application

- HVAC systems, Industrial ventilation ducts, Air Handling Units

- Color

- Silver, Grey, Custom

- Load Capacity

- Designed for low, medium, and high pressure ducts

- Usage

- Designed for isolation and shut-off of airflow in ventilation and HVAC ducts

- Diameter

- 100 mm to 1000 mm (for round types)

- Product Type

- Shut-off Damper

- Main Material

- Galvanized Steel / Mild Steel / Stainless Steel

- Surface Treatment

- Powder Coated / Painted / Galvanized

- Size

- Customizable as per requirement

- Weight

- Varies with size and material

- Feature

- Leakage proof, robust construction, corrosion resistance

- Shape

- Rectangular / Circular

About TAD Shut-off Damper

TAD (Tuned Mass Damper) dampers are devices that reduce vibration in structures such as buildings, bridges, and wind turbines. These devices function by adding a counteracting force that is out of phase with the structures vibration, thereby reducing the amplitude of the vibration.

A typical TAD damper is made up of a mass attached to the structure by a spring and a damper. The mass is intended to oscillate out of phase with the vibration of the structure, effectively reducing the amplitude of the vibration.

The spring allows the mass to move with the structure, while the damper dissipates energy from the system, reducing the amplitude of the oscillation. The stiffness of the spring and the damping coefficient of the damper is tuned to the natural frequency of the structure, ensuring that the TAD damper is most effective at reducing vibrations at that frequency.

Reliable Airflow Isolation for HVAC Systems

TAD Shut-off Damper delivers optimal isolation and control for ventilation ducts and air handling units. Its robust design and customizable construction ensure precise, leak-proof shut-off, making it integral to building safety and operational efficiency in commercial and industrial environments.

Flexible Installation and Operation

Designed for both horizontal and vertical mounting, the damper suits diverse ducting configurations. Multiple actuator optionsmanual, electric, and pneumaticallow for easy integration with existing air control systems while supporting varying operational needs and automation levels.

Engineered for Longevity and Corrosion Resistance

Constructed from high-quality materials and finished with advanced surface treatments, these dampers are built to withstand demanding conditions. Enhanced corrosion protection and a design life exceeding 10 years under recommended circumstances guarantee consistent performance even at elevated pressures and temperatures.

FAQs of TAD Shut-off Damper:

Q: How is the TAD Shut-off Damper installed in HVAC systems?

A: The damper can be installed using flanged, slip-on, or welded methods, accommodating both horizontal and vertical duct orientations. This flexibility allows it to fit a wide range of air handling setups and ducting specifications.Q: What materials are used in the construction of the damper, and why?

A: The dampers are fabricated using galvanized steel, mild steel, or stainless steel, chosen for their strength and corrosion-resistant properties. Surface treatments like powder coating, painting, or galvanizing further enhance durability in industrial environments.Q: When should a parallel blade design be selected over opposed blades?

A: Parallel blade designs are typically chosen for applications requiring higher airflow volumes and minimal resistance, while opposed blades offer more precise control of airflow and are preferred in balancing or throttling scenarios.Q: Where can the TAD Shut-off Damper be used?

A: These dampers are primarily used in HVAC systems, industrial ventilation ducts, and air handling units across commercial, manufacturing, and institutional facilities throughout India.Q: What process ensures the damper is leakage proof?

A: Each damper is equipped with an EPDM gasket seal, which guarantees air tightness and minimal leakage. Rigorous fabrication and quality control processes further uphold leak-proof operation during system use.Q: How does the actuator type affect operation?

A: Depending on requirements, the damper can be operated manually with a lever, or automatically with electric or pneumatic actuators. This allows for integration into manual or automated systems, adapting to variable control needs.Q: What are the benefits of choosing this damper for air control systems?

A: Selecting the TAD Shut-off Damper ensures precise airflow isolation, long-term reliability, high resistance to corrosion, and robust performance under high pressure and temperature conditions, making it a sound investment for ventilation infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Damper Category

Multi Louver Damper

Load Capacity : Medium Duty

Color : Silver / Grey / As Required

Product Type : Multi Louver Damper

Application : HVAC Systems, Industrial Ventilation, Air Handling Units

Weight : Variant (Depends on size and material)

Feature : Corrosion Resistance, Adjustable Louvers, Robust Construction

Butterfly Damper

Load Capacity : Suitable for normal industrial air flow loads

Color : Grey

Product Type : Butterfly Damper

Application : Ducting, Air Handling Units, Industrial Ventilation

Weight : 1550 kg (approx., varies by size)

Feature : Corrosion Resistant, Easy Operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry